| Main Functions: |

Specifications |

1. Filtering more than 90% harmful impurities in diesel fuel

2. Drawing off more than 95% water in diesel fuel

3. Reducing vehicle emissions up to 20% to 60%

4. Diesel fuel consumption reduced by 5% to 10%

|

The size of vat: 630×390×520mm

The size of input and output oil tube: Flange DN50

Rated flux: 0~150L/min

Rated pressure: 200KPa

weight:56Kg

|

| Main Advantages: |

Main Effects: |

1. Integrated multi-level filter technology

2. High filter fineness and working efficiency

3. Long replacement cycle for filter core

4. Low original resistance

|

1. Decreasing fuel consumption

2. Reducing engine failure and strengthening dynamic accordingly

3. Prolonging engine service life

4. Reducing maintenance cost for diesel engine and its diesel filter

|

THY-400S diesel oil purifier series are jointly developed by United States pre-filter Boston Co., Ltd and our tianhou group, which is mainly applied to oil storage facilities. This new invention is used for filtering harmful impurities for diesel engine; thereby attain the aims of purifying oil and protecting diesel engine. In China, the product has been applied to multiple companies running oil field large equipment, truck, fishery harbors diesel engine, ect, and gained surprising achievements and praise from clients.

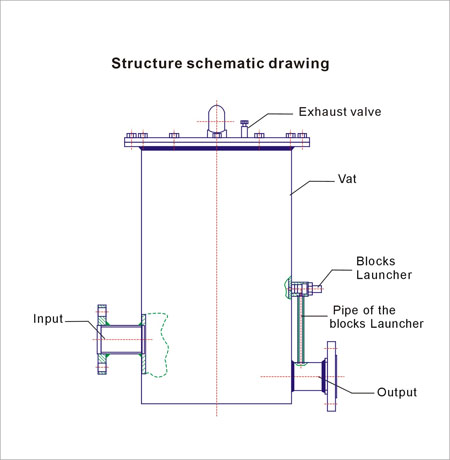

As is shown on the above image, we can see the product is made of stainless steel, reasonable design, compact structure, and easy installation. The unique design enables the "Janenope" diesel fuel pre-filter to have enough capacity to contain the contaminant in addition to the sufficiently prolonged time period for filter core replacement, with several times of purification effect higher than common diesel fuel pre-filters. The multi-level integrated filtration technology adopted ensures the elimination of more than 90% of harmful impurities (including tars, pitches and mechanical impurities) in diesel fuel.

| Ⅱ.Product function and installation: |

|

|

|

|

providing much cleaner diesel fuel for your application. For installation, users just need connect two barrels to the pipeline in parallel before using it. Please be careful and do not revert the output pipe and input pipe.The equipment has two vats in parallel. Users just connect two barrels to the pipeline in parallel before using it. Please be careful and do not revert the output pipe and input pipe. More careful for the exhaust when use it and replace the filter core the first time, exhaust valve is on the cover of the end vat.

| Ⅲ. Replacement of Filter Core: |

|

|

|

|

In normal situation, supposing the blocks launcher alarms(or the pressure gauge poiner turns to negative) when the equipment is running, the engine will be lack of diesel fuel at the moment, we should replace filter core immediatedly.

1) Close input valve, and open the upper cover.

2) Open the contamination valve to discharge polluted oil.

3) Loose the fixed screw on the upper end of the filter core, the opertor wear oil proof glove and catch hold of the filter core, and take out the old filter core vertically.

4) Replace the one core with the new core, place the upper seal mat (the lower with seal mat by itself) and install the nut.

5) Close contamination valve and place the upper cover (to be careful the seal mat) install tightly the bolt.

6) Open input valve firstly, then open exhaust valve. Close exhaust valve immediately when the exhaust valve exhaust, last open the output valve.

Application: THY-400S diesel oil purifiers can be mainly applied to various oil storage facilities.

|